Unsere Angebote jeden Monat neu

Sets und Bundles zu reduzierten Preisen

Ankerwelten

Unsere Empfehlungen für Sie

Im Mittelpunkt

die Freude am Bauspiel

Bauen mit Ankersteinen begeistert die Menschen seit 140 Jahren.

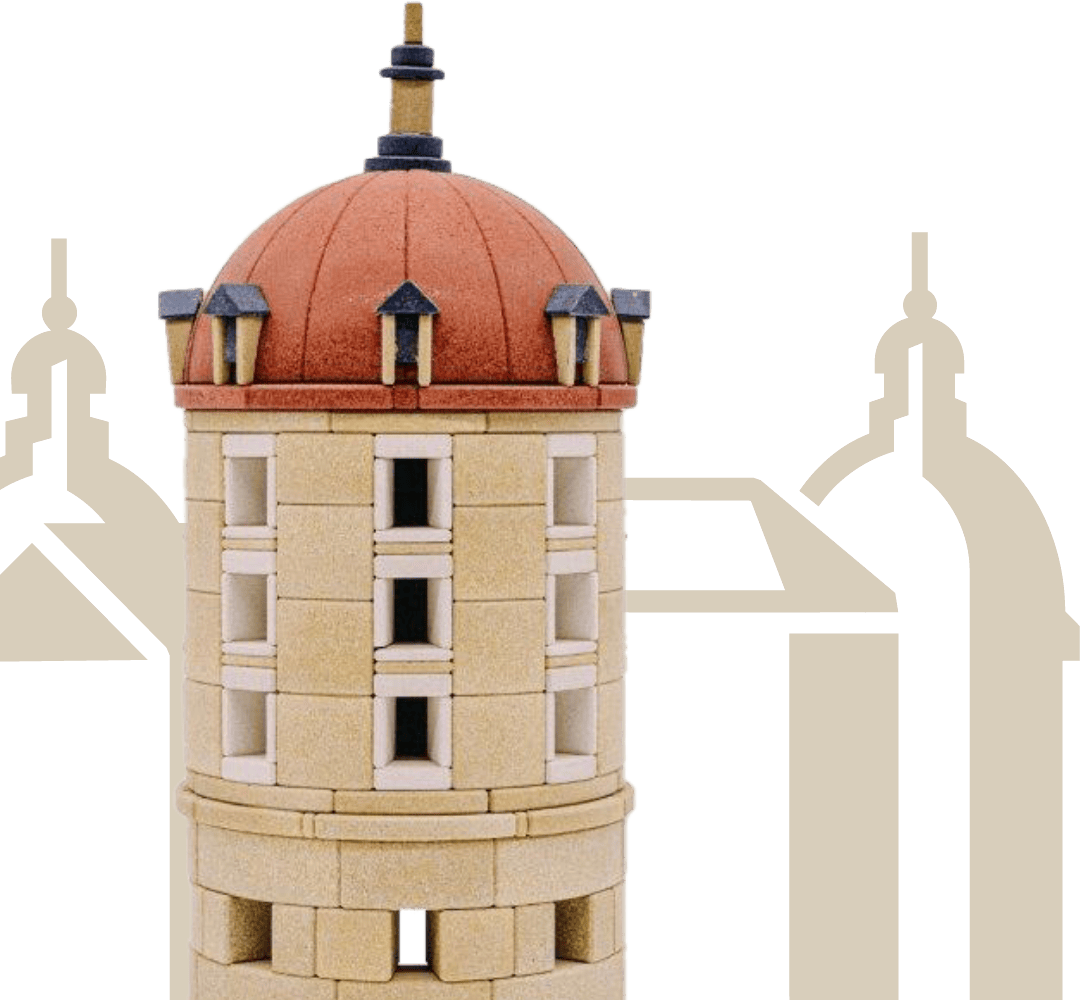

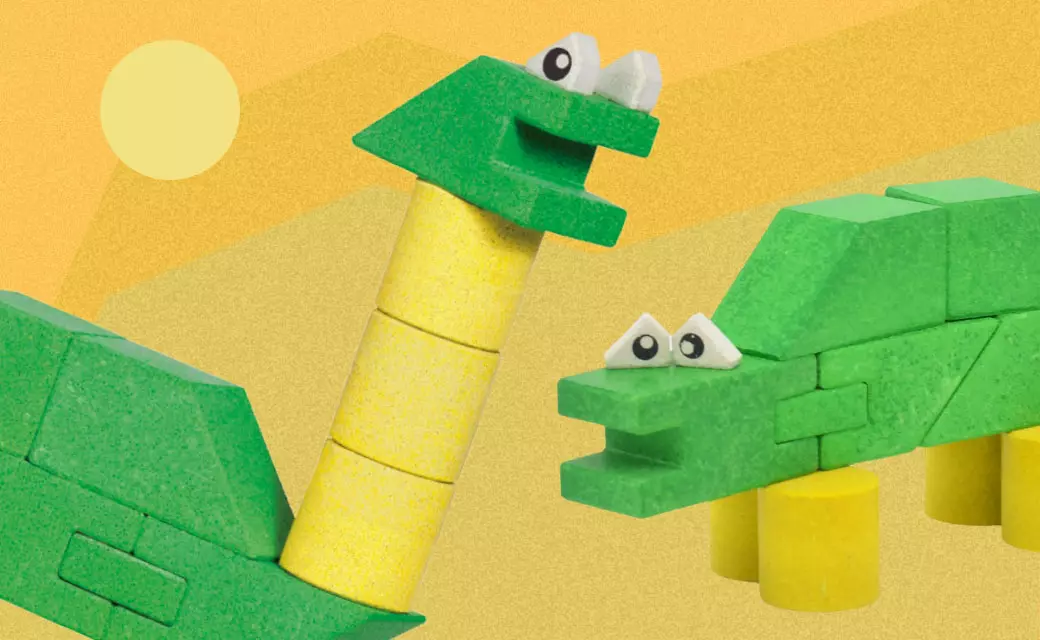

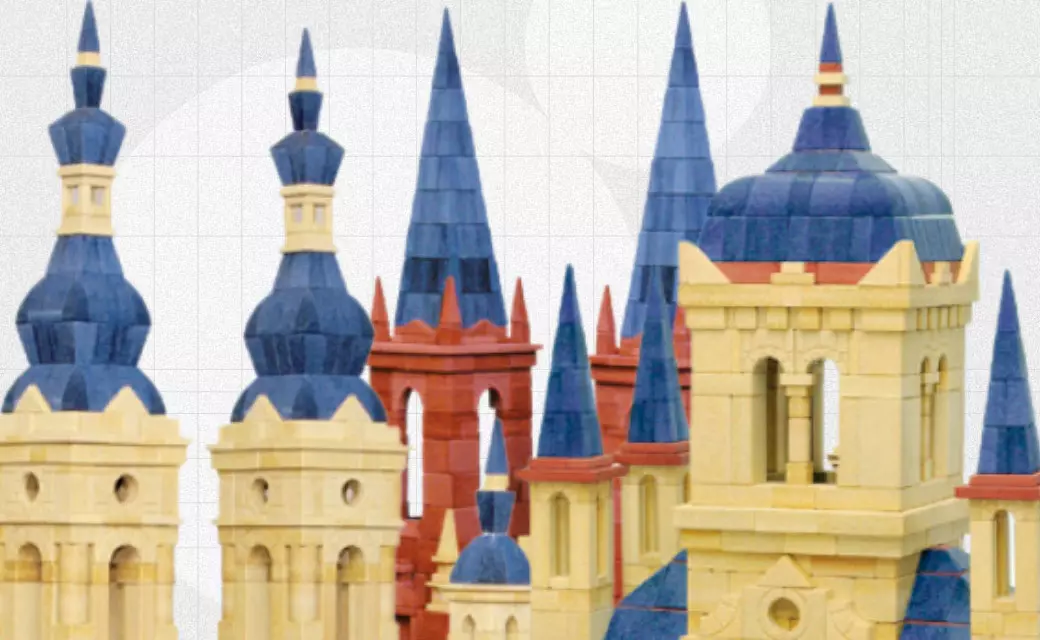

Es ist das Material, das fasziniert und das Anker von anderen Systemspielzeugen unterscheidet. Ankerbausteine sind echt! Sie sind aus Stein! Mittlerweile zählt der Bestand über 2.000 Formen. Jährlich kommen neue dazu, was die Sammelleidenschaft vieler Ankerfreunde beflügelt. Jeder Ankerstein ist präzise auf einen Zehntel Millimeter gearbeitet. Aufgrund von Eigengewicht und Struktur können auch große Bauten ohne Noppen oder Bindemittel errichtet werden.

Erlebe Ankerbausteine mit all Deinen Sinnen.

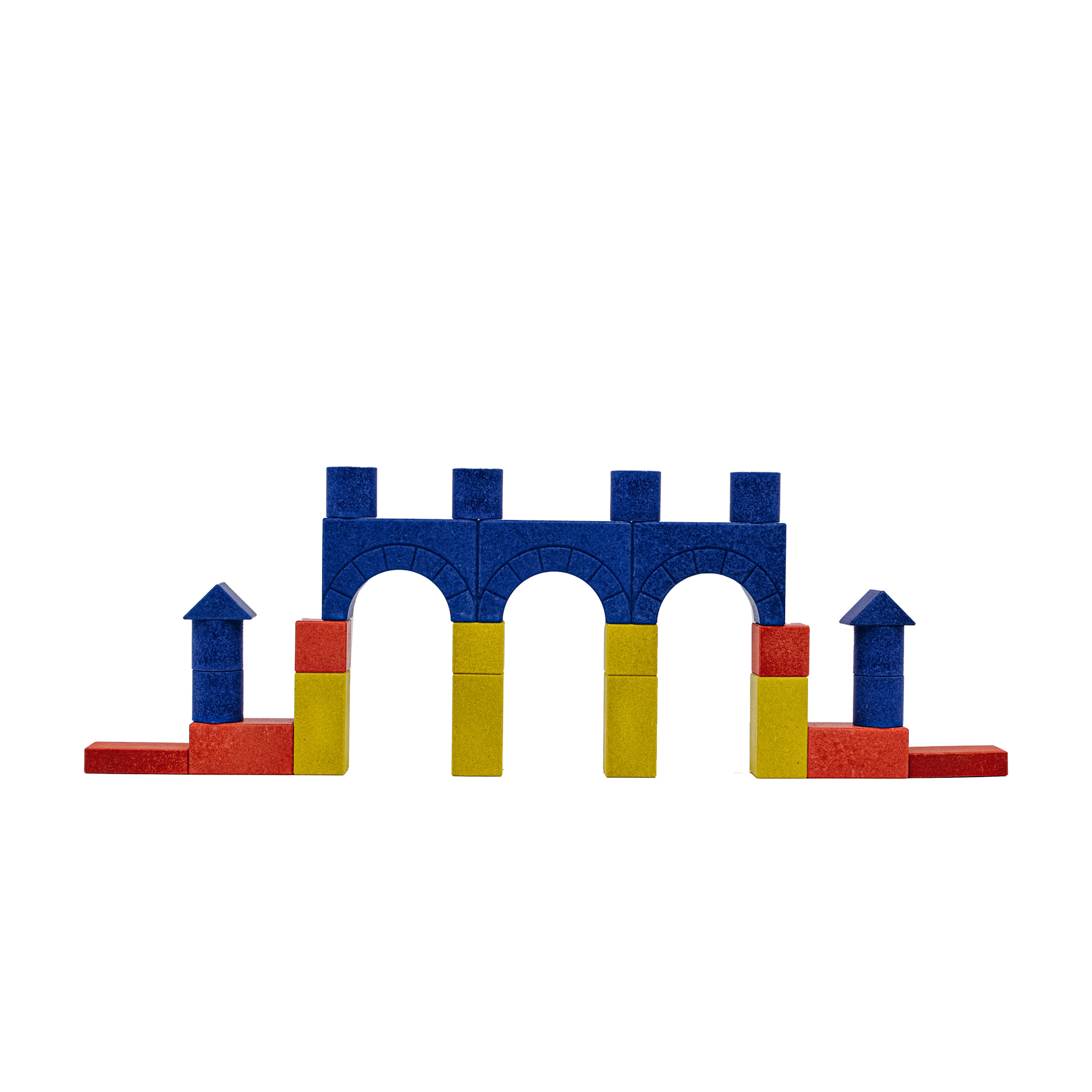

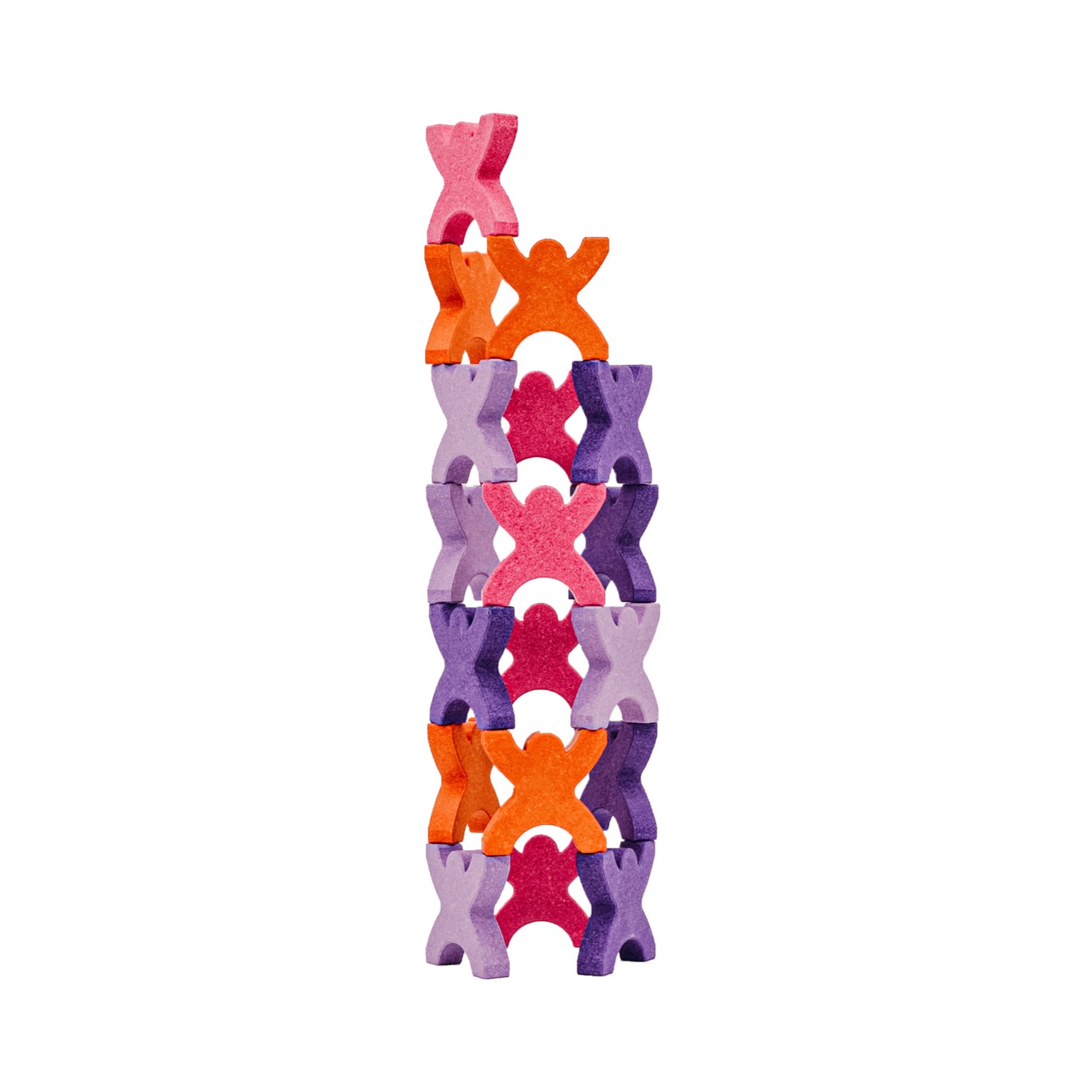

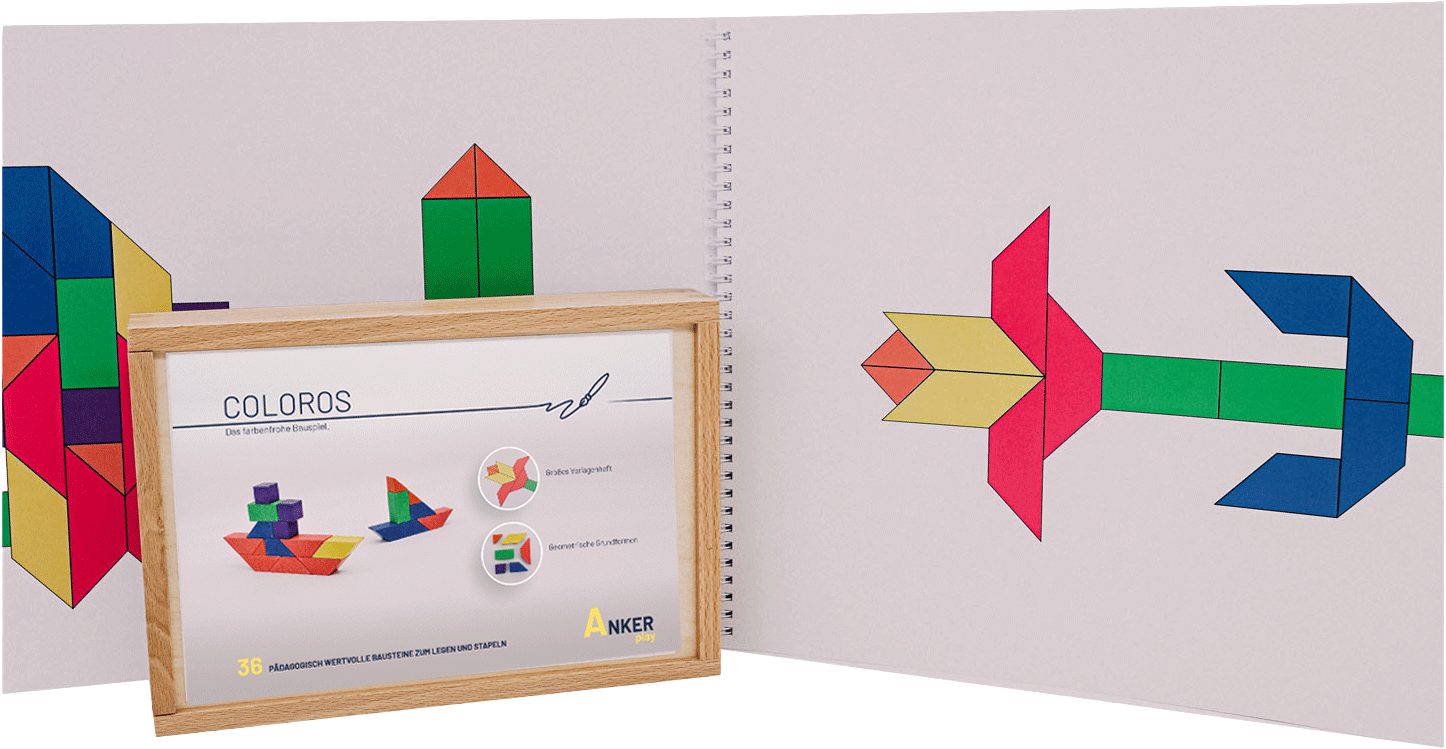

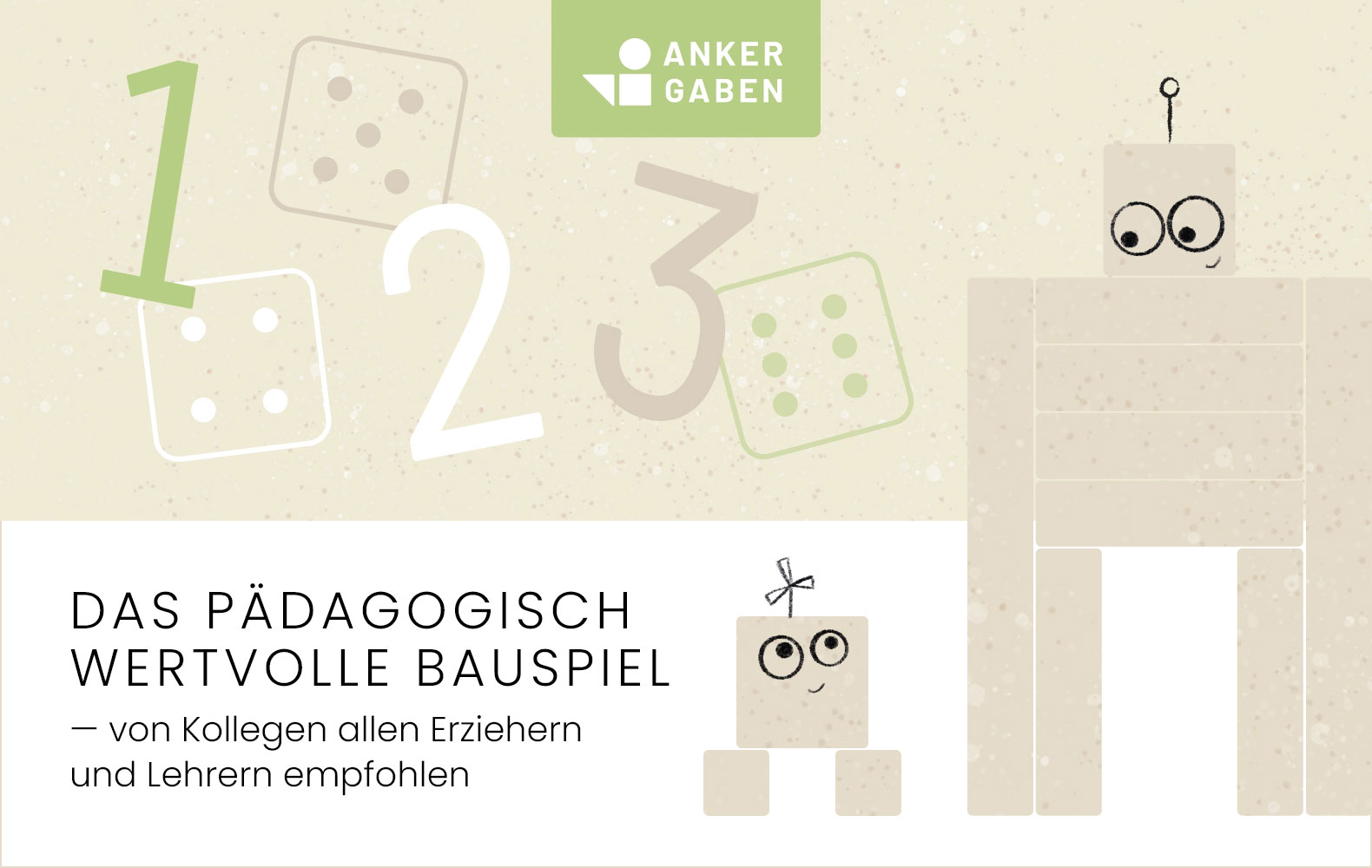

Lass Dich inspirieren vom Duft und der einzigartigen Oberfläche unserer steinernen Handschmeichler. Die neuen AnkerGaben sind speziell konzipiert für den fachkundigen Einsatz in Grundschulen und Kindereinrichtungen. Mit einer Kollektion klassischer Steine baust Du Häuser, Möbel, Tiere, Tore, Brücken und berühmte Bauwerke. Bauen, Spielen, Lernen - mit den pädagogischen Baukästen von ANKER macht das Spaß!

Die schönsten Geschenkideen

für Groß und Klein

Warum Anker?

Weil's nachhaltig und lebensecht ist!

Pädagogisch wertvoll seit 1884

Ankersteine sind das erste und älteste Systemspielzeug der Welt. Seitdem sie vor rund 140 Jahren ihren Siegeszug durch die Kinderzimmer Europas und Amerikas antraten, sind sie das Synonym für kreatives und pädagogisch wertvolles Spielen.

Nachhaltige Herstellung

Ankersteine werden nach traditioneller Rezeptur aus Quarzsand, Leinöl, Farbpigmenten und Kreide hergestellt. Sie sind absolut frei von Kunst- und Zusatzstoffen. Die Verwendung von ausschließlich natürlichen Rohstoffen erfüllt höchste ökologische Ansprüche.

Handarbeit

Ankersteine sind handmade in Germany. Das Anrühren der Steinmasse, Pressen der Bausteine, die anschließende Präzisionsmessung, Trocknung und Lagerung, letztlich das Bestücken der Holzkästen - alles erfolgt in liebevoller Handarbeit.

Inklusion

Bei ANKER begreifen wir Arbeit als Miteinander. Die Herstellung der Ankersteine in der Manufaktur erfolgt fair in der Zusammenarbeit eines integrativen Teams ganz unterschiedlicher Mitarbeiterinnen und Mitarbeitern.

Haptik und Präzision

Präzision, Oberfläche und Eigengewicht der Ankersteine ermöglichen ein Bauen ohne Noppen und Verklebungen. Das Zusammenhalten der Modelle basiert allein auf Statik. Die geringen Maßtoleranzen garantieren höchsten Baugenuss.

Echte Steine aus Leidenschaft

Ankersteine sind "echte Steine". Sie sind unkaputtbar, halten ein Leben und länger. Großmutters Steinbaukasten kann auch heute noch bespielt und mit neuen Ankerbausteinen ergänzt werden. Das schont Ressourcen und verbindet Generationen.